Magnetic fluidic seal (Magring Seal)

Bearing grease, gas, dust and other types of contamination can be removed completely with the air pollution prevention seal.

Special Features

- It is a one-piece construction, really easy one, compared to the original magnetic fluidic seal.

- Extremely thin design can be constructed: down to 1mm

- Possible to design a free shape of the seal

- Possible to use with shaft, housing materials: both magnetic and non-magnetic

Usage

Dust preventing seal

- Indirect seal for the clean robot

- PC Hard disc device

- spindle shaft seal

- head driving parts' seal - bearing seal

- Clean room's FA devices' seal

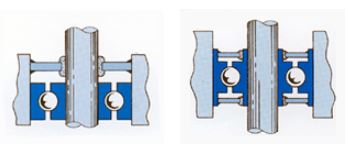

Example of magnetic fluidic seal usage

Assembled with the bearing

Mechanism of the magnetic fluidic seal

Magring seal is making the magnetic field without intervening the shaft.

(3-piece has to be made by using shaft and seal to make magnetic field, so the shaft material has to be magnetic)

Sizes, possible to manufacture

Magring Seal

| Outer Diameter | Less than 90mm phi |

|---|---|

| Inner Diameter | More than 20mm phi |

| Thickness | Less than 4mm |

| Seal Width | (One side less than 10mm) |

*Free to make a design with different shapes and measures of the specific molds

Magring seal measures: Example

|

<Machined products> etc. |

<Specific molds> etc. |

3-piece Mgnetic Fluidic Seal

| Outer Diameter | Less than 200mm phi |

|---|---|

| Inner Diameter | No limit |

| Thickness | 5mmt: fixed |

| Seal Width | No limit |

3piece magnetic fluidic seal measures: example

|

Φ100mm×Φ90.3mm×5mmt/Φ180mm×Φ175.3mm×5mmt etc. |

Following standard model are available for 3-piece Magnetic Fluid Seal

| ID(Φ)mm | OD(Φ)mm | Thickness(t)mm | |||

|---|---|---|---|---|---|

| 25.3 | +0.05 -0 |

40 | 0 -0.05 |

5 (4) | ±0.2 |

| 30.3 | +0.05 -0 |

45 | 0 -0.05 |

5 (4) | ±0.2 |

| 45.3 | +0.05 -0 |

60 | 0 -0.05 |

5 (4) | ±0.2 |

| 60.3 | +0.05 -0 |

80 | 0 -0.05 |

5 (4) | ±0.2 |

| 80.3 | +0.05 -0 |

100 | 0 -0.05 |

5 (4) | ±0.2 |

| 100.3 | +0.05 -0 |

120 | 0 -0.05 |

5 (4) | ±0.2 |

| 120.3 | +0.05 -0 |

145 | 0 -0.05 |

5 (4) | ±0.2 |

| 135.3 | +0.05 -0 |

160 | 0 -0.05 |

5 | ±0.2 |

| 150.3 | +0.05 -0 |

175 | 0 -0.05 |

5 | ±0.2 |

| 155.3 | +0.05 -0 |

180 | 0 -0.05 |

5 | ±0.2 |