Desktop nanoparticle generator

Desktop nanoparticle generator is a desktop type nanoparticle generator for research and development that generates high purity fine particles by spark ablation technology developed by VSparticle.

By adjusting the gas flow rate, spark energy and spark frequency, inorganic nanoparticles from single molecule to 20nm can be produced under the control of size, purity and particle component.

Nanoparticle technology

Nanoparticle is a substance made into particles of nanometer order

It is used in various fields such as semiconductor nanowires, quantum dots and nanocolloids in foods in addition to fuel cell and catalyst, since it is different from the general size material, having a very large specific surface area, or showing unique physical properties by quantum size effect, etc.

The problem of the current nanoparticle research is that the researchers spend a lot of time on the generation of nanoparticles and the essence of time in the research is limited, and that it needs also much efforts of the shifting from the research and development stage to the mass production.

VSparticle nanoparticle generator VS conventional method of Precipitation

| Generator Precipitation (conventional technology) |

VSparticle, Nano particle generator | |

|---|---|---|

| Process | Wet (liquid-phase) | Dry (gas-phase) |

| Particle size | Difficult to controll | Controlled |

| Purity | Surfactant, stabilizer impurities | High Purity |

| Process simplify | Costly intermediate steps | Simplify |

| Versatility | Different process for every particle | Any (semi-)conductive material |

| Waste | Chemical waste streams | No waste produced |

| Particle integration on product |

Solvent needs to be evaporated | Easily from gas phase |

Feature of VSparticle nanoparticle generator

- This product is the based on the principle of producing high purity nanoparticles by dry technique of spark ablation.

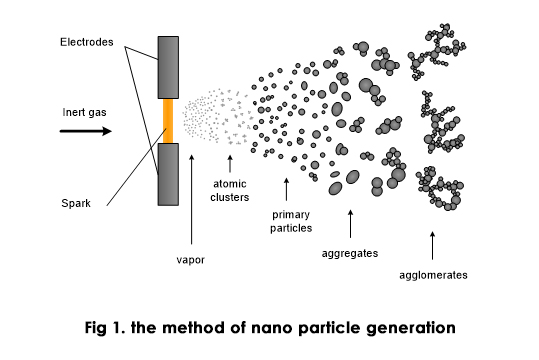

Produce nanoparticles according to the following procedure (see Figure 1)

1.Setting the electrode which becomes the particle source.

2.Introducing inert gas and sparking with high voltage.

3.generating Nanoparticles - Particle size, purity and composition of single electron ~ 20 nm can be controlled with adjustment of gas flow rate, spark voltage and spark frequency.

- Any metal, alloy, oxide film etc. can be produced (see application examples below).

Noble metals: Pt, Au, Ag, Ru, Rh, Pd, Ir, W

Other: Cu, Al, Fe, Mg, Ti, V, Nb, Cr, Mo, Mn, Co, Ni, Zn, Ga, Ge, Si, C, Pb, Ag, Cd, In, Sn, Sb

Alloys: Inox, Cu-Ni, Cr-Co, Au-Pd, Ag-Pd

Various oxides and doped materials: upon request. - A sealed reaction chamber configuration, which does not employ a polymer material in the ablation area, realizes high-purity particle generation.

- Compact desktop type is suitable to research and development.

- Cleaning and maintenance are also easily possible with a device configuration that is easy to disassemble.

- Safety such as spontaneous ignition prevention is considered by using inert gas.

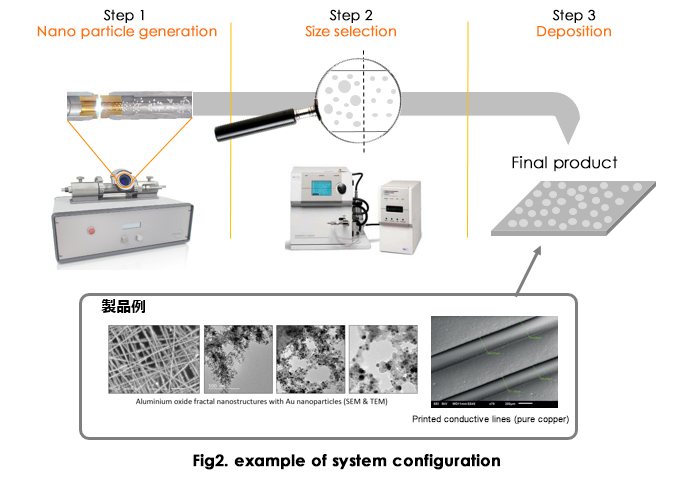

- A series of systems capable of adapting to final products is also proposed with generation of nanoparticles-> selection of particle size -> deposition (see FIG. 2).

Specifications

1)Unit specs

| Mains supply voltage/frequency |

110-240Vac, 50-60Hz |

|---|---|

| Power | 175 V-A |

| Dimensions | Casing ca. 52x30x20cm Reactor added height ca. 10cm |

| Weight | Base unit: 16kg Reactor assembly: 6kg Mount plate: 3kg |

| Gas inlet/outlet | 10mm tubes (with Swagelok connectors) |

| Display | 16x2 characters (Japanese display if requested) |

| Digital output | RS232 |

2)Operation specs

| Operation pressure | Atmosphere |

|---|---|

| Operation temperature | Room temperature |

| Flow rate | 1-30 L/min |

| Gas | Supported: Ar or N2 (recommended purity 5.0) Notification: Contact VSParticle for the use of reactive gases such as air and H2. |

| Electrode material | Comes with Cu electrodes. Various other metals (e.g. Ag, Au, Pt, W, Ni), semiconductors and carbon are possible. |

| Primary particle size | 1atm to 20nm |

| Ablation rate | >0.01-100 mg/h (material dependent) |

| Typical particle concentration | 108-1011 cm-3 |

3)Outer electro circuit

| Terminal | RS-232 |

|---|---|

| Connector | F-DE9 (sub-D, 9 pin) |

| Rating/specification | RS-232, only pins 2, 3, 5 connected |

| Voltage rating | Isolated 2.5kV |

Application

- Catalysis

- Electronics/sensor

- Battery

- Health care

- Solar cell

- Coating

- Inhalation studies

- Aerosol science

- Nano-toxicology

- Filter testing

- etc.

Data

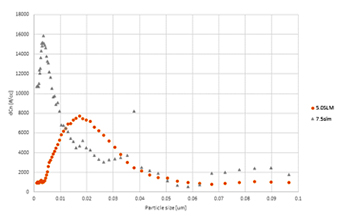

Ar gas rate variation (7W) (without size selection)

Increased flowrate leads to a narrower size distribution and smaller mean particle size.

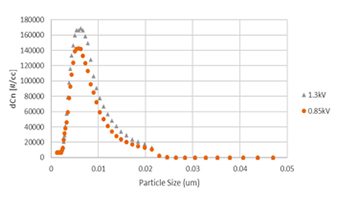

Voltage variation (5.0mA, 3.3slpm) (without size selection)

Increasing the gap voltage increases the spark energy. This means more mass will be ablated, leading to an increase in output.

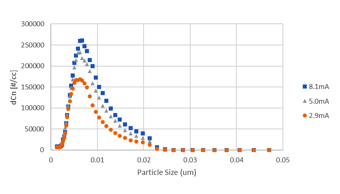

Current variation (1.3kV, 3.3slmp) (without size selection)

Increasing the current increases the spark frequency. More batch processes (sparks) will occur, increasing mainly particle count.

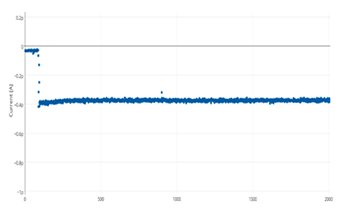

Cu, 12.5slpm, Ar (5nm size selected particles)

100s after starting the spark generator and electrometer, the first particles hit the Faraday Cup.

Average (t100-t2000) = -0.377 pA STDV(%) = 2.1

The current is measured by a Keithley electrometer and is directly proportional to the particle output.

検索用入力欄

記入時注意事項

- テーブルの行列は変更しないでください。

- 分類が複数ある場合は、| ←半角の縦棒で区切って連続で入力してください。

また、区切り文字の前後に空白は入れないでください。

| 製品分類1 | Microfabrication Tools|Precision Cleaning / Dryice blast |

|---|---|

| 製品分類2 |

|

| プロセス分類 | Process & Equipment |

| サムネイル画像 |

|

| 説明文 |

|

| リダイレクトURL |

|