Nanoimprint Lithography Total Solution :from molf to imprint services

Nanoimprint lithography is one of upcoming technology which enables pattern transfer from fine patterned mold to regin or glass substrates.

Kyodo International offer 1) Mold (Stamper) fabrication services and 2) Imprint service in order to answer our clients' needs decreasing their R&D costs.

Mold Fabrication & Nanoimprinting Services

Master Fabrication Service

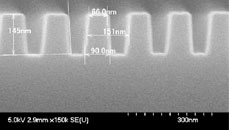

Si Master

- Si

- This is the best material to use as master mold as it is easy to process and allows to imprint all kinds of patterns from mm order down to nm order with high aspect ratio. It is also possible to perform Ni electroforming.

Items Master / Mold Materials Polymer Nanoimprint We can use our own NIL process

Resist Master

- Resist

- Such molds have exceptional photolithography process stability. It is possible to create 3D patterns such as lens and others. Using the resist mold as a master mold, it is possible to do electroforming therefore obtaining a Ni mold.

Items Master Materials Polymer

Mold Fabrication Service

Si Mold

- Si

- This is the best material, as it is easy to process and allows all kinds of measures. You can decide the width from mm.

Items Master / Mold Materials Polymer Nanoimprint We can use our own NIL process

Ni Electroforming Mold

- Ni

- It is possible to create a Ni mold using Si and resist molds as masters. Ni molds are superior to Si and glass molds in terms of hardness and it is easy to recreate a copy from a master.

Items Mold / Imprinting Materials Polymer Nanoimprint We can use our own NIL process

Quartz Mold

- Quartz

- For molding applications we use Pyrex, Tempax and other low melting point glasses.The main material used for molds is quartz.

Metal Mold

- Metal

- Using Ti or W as material, it is possible to have the size of the pattern as thin as that of Si and glass molds. The main advantage of metal molds is that they can be used to imprint on glass. Our company has developed a set of unique metal molds.

Items Mold / Imprinting Materials Polymer / Glass Nanoimprint We can use our own NIL process

Diamond Mold

- Diamond (under development)

- Diamond has great material properties as for thermal expansion, thermal resistance, thermal conductivity, hardness, tolerance to abrasion, demolding easiness, etc. It is especially suitable for nano-imprinting on glass.

Items Mold / Imprinting Materials Glass

Trial Mold for Nanoimprinting

Nanoimprinting Service

Fine Pattern Imprinting on Various Optical Films

- Polymer

- For trial imprinting the most suitable resist types are: PMMA, polyca, polyamide, polyester, COC, COP, etc. We can offer original imprinting services for other resin types supplied by the customer.

Resist Patterning (on Si, Glass, Sapphire, .. substrates)

- Resist

- It has exceptional stability, when it comes to photolithography processing. Lens and other forms can be made 3D. The resist will be made a master and Ni electroforming will be brought, which will have NIL application possible.

Items Master Materials Polymer

Glass Fabrication

- Glass

- This is a material which is suitable for UV imprinted molds. The pattern width can be decided as freely as it can be done for Si molds. It is not possible to reach the same depth degree that you can achieve with Si molds but the glass transparency can be used for making microfluidic chips.

Items Master / Mold Materials Polymer Nanoimprint We can use our own NIL process

PSS volume production system TEX Series »

Nanoimprint engineering & solutions »

検索用入力欄

記入時注意事項

- テーブルの行列は変更しないでください。

- 分類が複数ある場合は、| ←半角の縦棒で区切って連続で入力してください。

また、区切り文字の前後に空白は入れないでください。

| 製品分類1 | Nanoimprinting |

|---|---|

| 製品分類2 | MEMS Prototyping|Microfluidics |

| プロセス分類 | Prptotyping, R&D|Volume production|Process & Equipment|Others |

| サムネイル画像 |

|

| 説明文 |

|

| リダイレクトURL |

|